Airflow Water Wash Spray Booths are supplied with their Washing Chamber section fully assembled for final site fitting of their Fans and Canopy section. This ensures a properly engineered and sealed washing system and, dramatically reduces site installation time. All Airflow Spraybooths are designed to both meet the latest European regulations and comply with HSG 178 - The Spraying of Flammable Liquids and they carry the benefit of the CE mark if destined for supply within the EC. The fan used on all Airflow Spraybooths is our unique 'cartridge' style design, specifically developed for use in aggressive environments where solvents and other dissolved contaminants within the exhaust air stream can quickly shorten the life of a conventional fan.

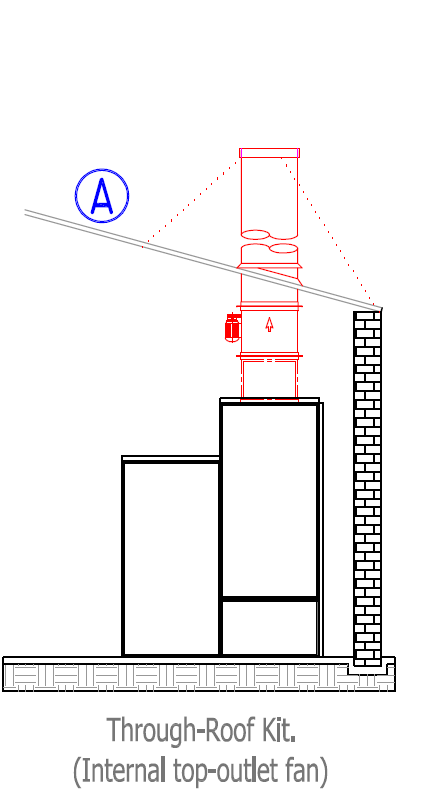

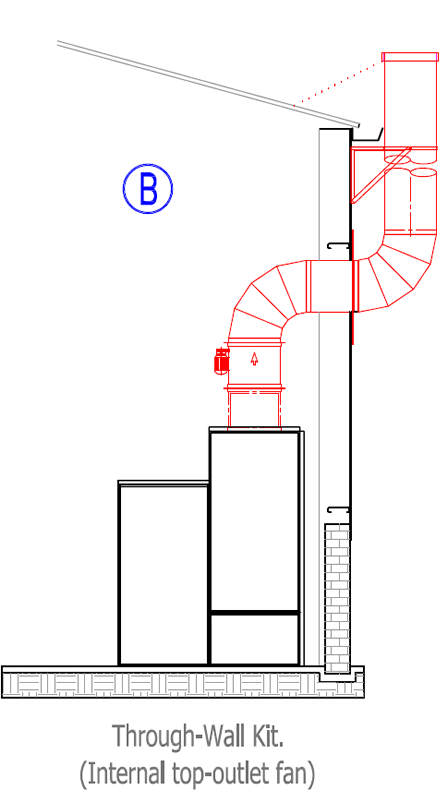

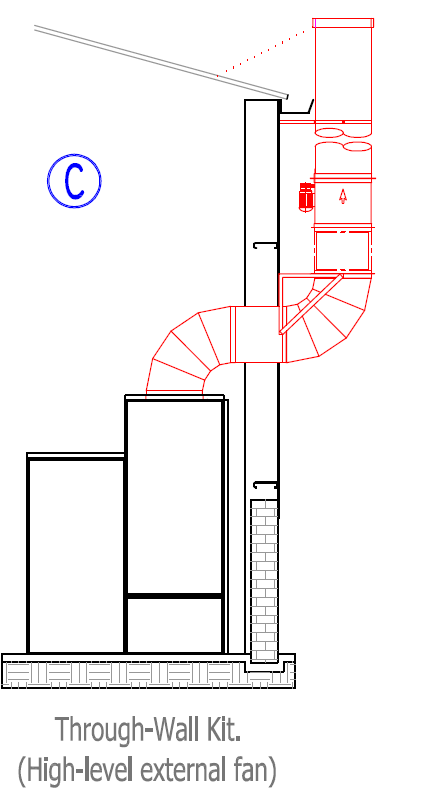

Water Wash Spray Booth Ducting Kit Options

External Dimensions

External Dimensions

- 2.9m high* x 2.2m wide^ x 2.25m deep (*Excluding 0.55m long fan, ^Excluding 0.32m wide pump)

Internal Working Area

- 2.2m high x 2.1m wide x 1.1m deep (extendable by standard modules)

Ventilation

- 1 x Airflow 3.0kW (415/3/50 non-flp) belt-driven axial flow fan

- 1 x 630mm diameter flue to atmosphere

Water Circulation

- 0.75kW (415/3/50 non-flp) Lowara pump set with stainless-steel impellor and Tungsten Carbide seal

Noise Levels

- Booth face: unattenuated - 78dB(A) attenuated - 64dB(A)

- Free field: unattenuated - 77dB(A) @ 3 duct dia (approx)

- *Noise levels are provided for guidance purposes only, as they are likely to be affected by other factors, e.g. additional sources of noise within the surrounding area, type of filter medium, installation format, etc.

Construction

- Booth - 1.2mm prime galvanised-steel CNC punched and formed panels, uniquely styled for simple assembly, providing greater rigidity and aesthetic finish

- 2mm mild-steel fully welded and two-coat epoxy-painted tank

- Full width stainless-steel Water Curtain Screen

- Heavy-duty welded and screwed/socketed pipe work (with no rubber-type joints)

- Externally mounted gate valve

For wet sprayed applications a suitable Chemical Additive must be added to the Booth's water to denature finishes entering the re-circulating water. This will extend periods between routine maintenance and control the efficiency of the Booth. Additionally, a biocide should be applied to the water to protect against a range of bacteria which can disseminate into breathable droplets. Please refer to approved code of practice guidance note L8. An application of Peelable Coating to the inner face of the canopy will further simplify maintenance, reduce fire risk and, prolong the life of your installation. Consideration should be given to the need for replacement air which, in volume, should equal that being ventilated whilst fans are in operation, for which Airflow offer a full range of Heated Air-replacement Units.